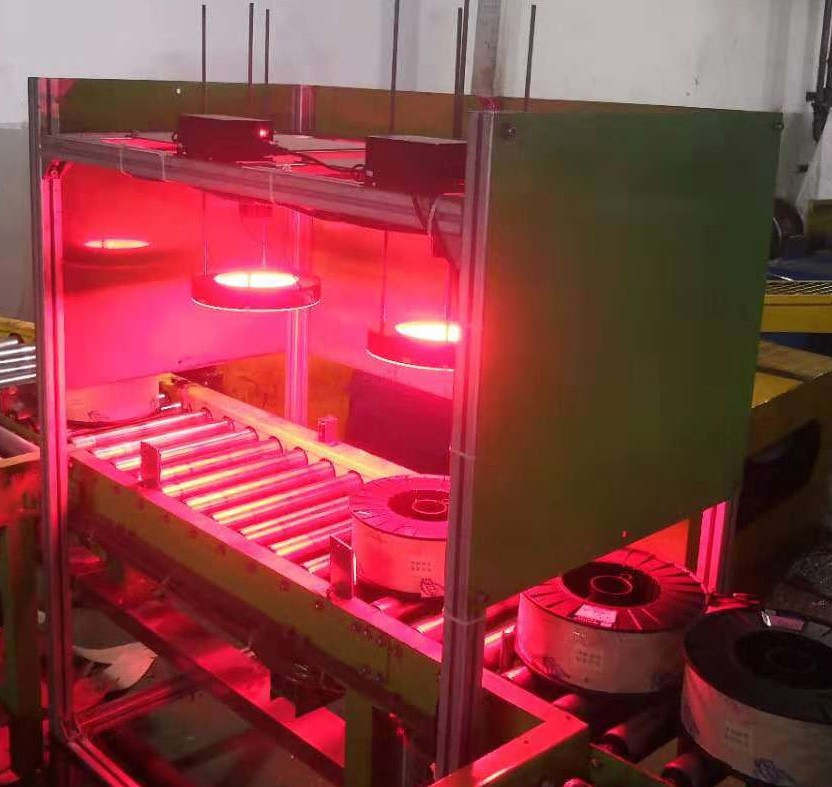

Automatic visual detection system

Detection object description: size, photo, material, color, etc.

Operation object: identify the inspection number on the label and count the production quantity of different inspection numbers.

Description of inspection requirements: Each shift records the statistical quantity of different inspection numbers of the previous shift before production, and then clicks the clear button to clear the data and start the production quantity statistics of this shift. The vision system recognizes the inspection number on the label and counts the production quantities of different inspections. Can automatically identify the product batch number, specification, weight, inspection number, QR code, and barcode on the label.

|

Automatic visual detection system |

|

|

Model |

KB-S1200 |

|

Field of view |

cover the whole welding wire coil |

|

Speed |

more than 6 times a minute |

|

Installation height |

700±50mm |

|

Camera trigger method |

PLC+photoelectric switch external trigger |

|

Camera resolution |

2448*2048 |

|

Accuracy |

0.18mm |